This case study is just one of the very best Award-Winning Examples of Successful Operational Excellence from the Business Transformation & Operational Excellence Awards, 2017. You can learn more about the awards here.

This case study is just one of the very best Award-Winning Examples of Successful Operational Excellence from the Business Transformation & Operational Excellence Awards, 2017. You can learn more about the awards here.

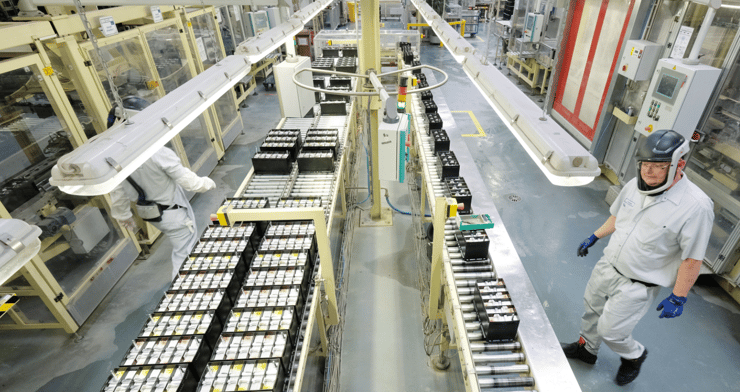

Johnson Controls launched a Manufacturing Excellence Strategy at the end of 2013 to achieve its vision of becoming one of the most operationally capable companies in the world. The centerpiece of the strategy, which was developed by a global cross business unit team, is the Johnson Controls Manufacturing System (JCMS).

Enabling dimensions of the strategy include: an operations academy; a web application for assessing a baseline, establishing action plans and real-time reporting of progress; high performance teams (HPT) that empower the shop-floor employees and hold them accountable for improvement; regional subject matter experts (SMEs).

JCMS was initially introduced to all business unit operations leaders responsible for the company’s more than 300 plants around the globe in September 2014. Immediately after deployment, the company launched a JCMS acceleration phase in 2015 that focused on building manufacturing capabilities, implementing quick wins and removing waste in one model line per plant to demonstrate results and to drive quick adoption of JCMS.

Ricardo Estok, Manufacturing Excellence Transformation Leader, drives the strategy for employees being empowered and accountable for its own performance improvements in core KPIs

View more Operational Excellence Award Winning Case-Studies

Initially 300+ plants worldwide, involving 120,000+ employees and all business units. After the spin of the Automotive business and the merge with Tyco, the current Johnson Controls manufacturing footprint is 130 plants, with 50,000+ employees.

After merging with Tyco in 2016, the company began executing an integration strategy to deploy JCMS to the legacy Tyco plants globally. A team of legacy Johnson Controls and Tyco employees systematically evaluated each company’s manufacturing practices and incorporated the best of both into a new iteration of JCMS for all plants.

Read More: Lean Six Sigma Resources

- The extent of cultural change reaches all Manufacturing organizational levels, from Senior Manufacturing Leaders to shop-floor employees. They collaborate with each other and work as one team to drive excellence as a result of the JCMS practices as Gemba, Kaizens and High Performance Teams.

- An Operations Academy that has developed 31 learning solutions to build capabilities from operations leadership to the shop floor.

- Acceleration and replication phases embedded in JCMS processes through a “learning by doing” approach that have increased capabilities and demonstrated cost savings as well as performance improvements.

- The JCMS web application with 2,000+ users provides a platform for real-time dissemination, management, reporting and tracking of best manufacturing practices.

- High performance teams, creating a framework for the shop floor being empowered and accountable for its own performance improvement in core KPIs.

- An incentive structure that offers visibility and accountability to all team members to focus on business unit and enterprise KPIs.

- A leadership model embedded in the operations organization allowing for the resource infrastructure to build and sustain success.

Overall Impact of Operational Excellence deployment:

Some examples include:

JCMS is recognized within JCI, and is being recognized throughout the industry. Recent awards include:

For additional information, please contact Ricardo Estok, at francisco.ricardo.estok@JCI.com, or download the full Case Study below.

Get the Case Study Now:

The centerpiece of this case study strategy is the Johnson Controls Manufacturing System (JCMS). The system has four foundations – customer focus, stable production environment, zero tolerance for waste, and organize around pull – and nine principles that provide a comprehensive model with clear roadmaps for engaging employees, driving manufacturing excellence and growing the business via One Johnson Controls Way of manufacturing.

About the Author

Ricardo Estok, has over 20 years of experience driving sustainable Operations, Commercial and Business Excellence Transformations. He has multicultural and functional experience at global companies in the US and LA, including Johnson Controls, S.C. Johnson, Abbott and Pepsi.

Currently, his role is as the Enterprise Principle Leader, Global Manufacturing Operations & Council at Johnson Controls Inc.

View our schedule of industry leading free to attend virtual conferences. Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

View Schedule of EventsWelcome to BTOES Insights, the content portal for Business Transformation & Operational Excellence opinions, reports & news.

-------------------------------------------------------

Search for anything

Insights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to attend this premier virtual conference, and they will receive an invitation to attend.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

View our schedule of industry leading free to attend virtual conferences. Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

View Schedule of EventsWatch On-Demand Recording - Access all sessions from progressive thought leaders free of charge from our industry leading virtual conferences.

Watch On-Demand Recordings For FreeDelivered by the industry's most progressive thought leaders from the world's top brands. Start learning today!

View All Courses NowThe premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free. Use code: BFH1120

Watch On-DemandInsights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to also access our newsletter. They will receive an invitation and an option to subscribe.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

Read this article about HP, Best Achievement in Operational Excellence to deliver Digital Transformation, selected by the independent judging panel, ...

Read this article about BMO Financial Group, one of our finalists, in the category Best Achievement in Operational Excellence to deliver Digital ...

Read this article about Cisco, one of our finalists, in the category Best Achievement of Operational Excellence in Internet, Education, Media & ...