BTOES From Home - SPEAKER ...

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

View our schedule of industry leading free to attend virtual conferences.

Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

Watch On-Demand Recording - Access all sessions from progressive thought leaders free of charge

from our industry leading virtual conferences.

The premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free.

Use code: BFH1120

Delivered by the industry's most progressive thought leaders from the world's top brands.

Start learning today!

What does it take to implement Business Process Excellence, Continuous Improvement, or Process Improvement in your business?

Jump to any section

What is Continuous Improvement?

The Continuous Improvement Model

The 4 Pillars of Continuous Improvement

The Benefits of Continuous Improvement

What are the Key Challenges to Embedding Continuous Improvement

What is Continuous Improvement?

There is undoubtedly a clear connection between Operational Excellence and Continuous Improvement - however, Operational Excellence is arguably a far more specific and definable term. Continuous Improvement more widely marks the process of persistently seeking to improve business process, products and services. Where 'Operational Excellence' is a target state to attain through various practises, Continuous Improvement refers more to the ongoing journey of improvement.

Read more: Continuous Improvement - High-Tech or High-Touch?

Kaizen is Japanese and stands for "Continuous Improvement". It refers to activities aiming for the implementation of positive, ongoing changes at the work station. In other words, it is a strategy that involves all employees from every company level to work together and proactively with the goal of achieving regular, incremental improvements to the manufacturing process.

Kaizen puts emphasis on the significance of continuous improvement. It is not enough to undertake changes once. Organizations have to make an effort in continuing improvements repeatedly. Numerous companies have applied Kaizen's concept and strategy in order to increase employee productivity, reduce costs, and improve the overall customer experience.

Six Sigma is a set of tools and techniques for the improvement of business processes. The goal is to create customer experience improvement by means of variation's identification and elimination. This can be accomplished by the implementing DMAIC, a Six Sigma sub-methodology. DMAIC is the abbreviation for:

- Define: define the problem in order to solve it.

- Measure: measure all of your available data as well as take a more detailed look into your processes.

- Analysis: perform analysis of your findings and figure out the problem's root.

- Improvement: once you analyzed your data, find possible solutions and implement them.

- and Control: ensure to maintain your new implemented process.

Lean is focused on eliminating waste from the process without negatively impacting productivity. In other words, it aims to implement business processes that achieve high quality, safety and worker morale and reducing cost as well as shortening lead times at the same time.

Furthermore, waste is any activity or expenditure of resources that does not add value from the customer's point of view. In Lean manufacturing, there are seven types of waste identified:

Read more: Transitioning to Lean

Read more: 10 Top Tips for Implementing Lean Successfully

Read more: Creating a Lean Culture of Problem Solving

Read more: Lean Business Transformation & Operational Excellence in Healthcare

Read more: Lean-Driven Innovation

Kaizen aims the improvement of the business as a whole. The goal is to increase efficiency and eliminate business waste by creating and implementing standard work.

On the other hand, the concept of Six Sigma puts emphasis on the quality output, the final product. This strategy involves finding and eliminating the roots and causes of defects.

Lean approaches are generally about the elimination of waste in order to increase the speed of processes. Quality improvement can be achieved by reducing waste in processes.

One thing all three concepts have in common is that all of them lead to the development of an effective continuous improvement model. However, as the definitions mentioned above, the approaches are distinct and have to applied differently, depending on the problem that needs to be resolved.

Read more: What is the Best Way to Begin a Lean or Continuous Improvement Journey?

Read more: Creating a Lean and Continuous Improvement Culture in your Business

Read more: The Bose Lean Journey

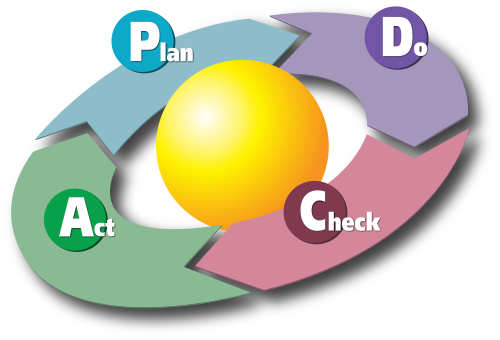

The most common Continuous Improvement Model is presented as a cycle or a wheel, the so-called Continuous Improvement Cycle. The reason for this is its ongoing movement and nature of change. Once you completed the last stage of "Act", the circle starts at "Plan" again, so it is a never-ending routine.

Derived from that it can be said that continuous and process improvement is a commitment. Applying the Plan-Do-Check-Act model will support your organization in terms of continuous learning and performance excellence.

Read more: The Root Cause of All Problems: Identify your Continuous Improvement 5 'Whys'

Read more: The 6 Mistakes Most Businesses Make When Adopting a Continuous Improvement Program

The path to performance improvement and business efficiency improvement is to truly understand your surroundings, your current way of working, your business processes and where exactly changes and improvements have to be taken place.

Read more: Sustaining a Continuous Improvement Culture

Continuous Improvement is a technique of Lean improvement that supports the optimization of workflows. Efficient workflows do not only save time and money, but also enables reducing wasted time and effort. Moreover, by using Forecasting Software, project management offices can cut costs and prevent surpluses, which also increases their overall effectiveness for the company. What is more, documenting your processes will create a specific consistency, which makes it easier for predictions, monitoring and, most of all, assurance of a certain level of success. To be more precise, continuous improvement advantages are relatively simple. You constantly better your practises to make your team and business more efficient, accurate, and effective. However, there is one thing to remember: Improvement is not a one-time event. There will always be room and capabilities to implement changes to your business processes and methods.

Read more articles on Continuous Improvement:

Meaningful Purpose: Develop Organizational Momentum that Fosters Continuous Improvement

How Can Healthcare Create High Reliability Organizations Using Continuous Improvement Methodologies?

Leading Culture Change through Lean Leadership & Continuous Improvement

How 'Managing Up' can Boost Your Continuous Improvement Results

How to Choose Metrics to Drive Continuous Improvement

The Fast Lane to Operational Excellence

Welcome to BTOES Insights, the content portal for Business Transformation & Operational Excellence opinions, reports & news.

Insights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to attend this premier virtual conference, and they will receive an invitation to attend.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

View our schedule of industry leading free to attend virtual conferences. Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

View Schedule of EventsWatch On-Demand Recording - Access all sessions from progressive thought leaders free of charge from our industry leading virtual conferences.

Watch On-Demand Recordings For FreeDelivered by the industry's most progressive thought leaders from the world's top brands. Start learning today!

View All Courses NowThe premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free. Use code: BFH1120

Watch On-DemandInsights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to also access our newsletter. They will receive an invitation and an option to subscribe.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

Read this article about HP, Best Achievement in Operational Excellence to deliver Digital Transformation, selected by the independent judging panel, ...

Read this article about BMO Financial Group, one of our finalists, in the category Best Achievement in Operational Excellence to deliver Digital ...

Read this article about Cisco, one of our finalists, in the category Best Achievement of Operational Excellence in Internet, Education, Media & ...