BTOES From Home - SPEAKER ...

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

View our schedule of industry leading free to attend virtual conferences.

Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

Watch On-Demand Recording - Access all sessions from progressive thought leaders free of charge

from our industry leading virtual conferences.

The premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free.

Use code: BFH1120

Delivered by the industry's most progressive thought leaders from the world's top brands.

Start learning today!

The Toyota Production system is a major precursor of Lean Manufacturing. Founded on the conceptual pillars of 'Just-in-time' and 'Jidoka' (or, Automation with a Human Touch), the system was first built off the approach created by the founder of Toyota, Sakichi Toyoda and his son, Kiichiro Toyoda.

Read More: What is Lean?

The main target of the Toyota Production is to eliminate 3 key issues: Overburden, Inconsistency, and Waste - or 'Muri', 'Mura' and 'Muda', respectively. Theoretically, process improvement working like so:

- A process is created that is easily repeated, and provides results smoothly, thus eliminating Inconsistency in the production line (Muri).

- This reduction in Inconsistency minimises Stress, or Overburden (Mura), as there are less mistakes being made.

- The lack of Stress in turn massively reduces Waste (Muda), which is considered to occur in 8 forms:

Dan Markovitz, Founder/President of Markovitz Consulting, Author

The corporate landscape is full of Operational Excellence companies that have failed in their pursuit of the ‘Toyota Way.’

Trying to be like Toyota is a mistake. A “fit” organization has the ability to continually improve in a manner that delivers superior performance and results over the long haul.

This Operational Excellence example study, based on the Shingo Research Award-winning book, "Building the Fit Organization," distills the lessons from the Toyota Production System into six core concepts, in the easily understandable language of physical fitness and athletic excellence—no Japanese, no English jargon, and no references to Toyota. Give your team the knowledge to be faster, more competitive, and better able to win in your market.

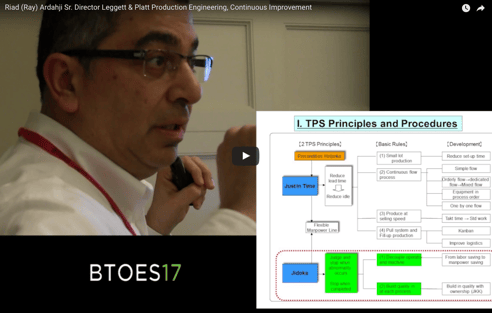

The Toyota Production System is grounded on two main conceptual pillars:

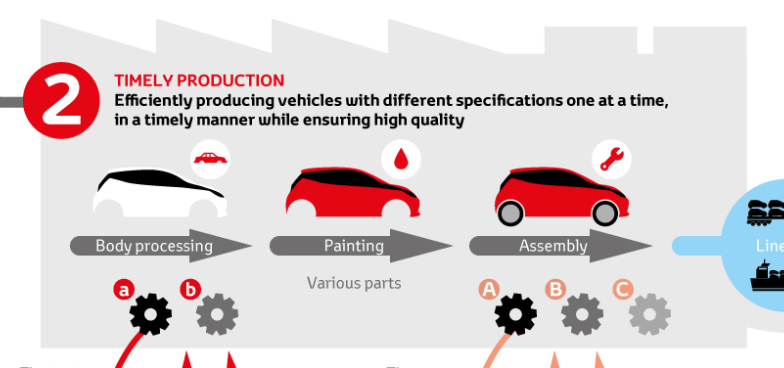

With 'Just in Time', a product is efficiently built within the shortest possible period of time by adhering to the following:

For the Just-in-Time system to function, all parts that made and supplied must be meeting predetermined quality standards. This is achieved through Jidoka.

Welcome to BTOES Insights, the content portal for Business Transformation & Operational Excellence opinions, reports & news.

Insights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to attend this premier virtual conference, and they will receive an invitation to attend.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

View our schedule of industry leading free to attend virtual conferences. Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

View Schedule of EventsWatch On-Demand Recording - Access all sessions from progressive thought leaders free of charge from our industry leading virtual conferences.

Watch On-Demand Recordings For FreeDelivered by the industry's most progressive thought leaders from the world's top brands. Start learning today!

View All Courses NowThe premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free. Use code: BFH1120

Watch On-DemandInsights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to also access our newsletter. They will receive an invitation and an option to subscribe.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

Read this article about HP, Best Achievement in Operational Excellence to deliver Digital Transformation, selected by the independent judging panel, ...

Read this article about BMO Financial Group, one of our finalists, in the category Best Achievement in Operational Excellence to deliver Digital ...

Read this article about Cisco, one of our finalists, in the category Best Achievement of Operational Excellence in Internet, Education, Media & ...