BTOES From Home - SPEAKER ...

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

Supply chain planning (SCP) is the forward-looking process of coordinating assets to optimize the delivery of goods, services and information from supplier to customer, balancing supply and demand. An SCP suite sits on top of a transactional system to provide planning, what-if scenario analysis capabilities and real-time demand commitments, considering constraints. Typical modules include:

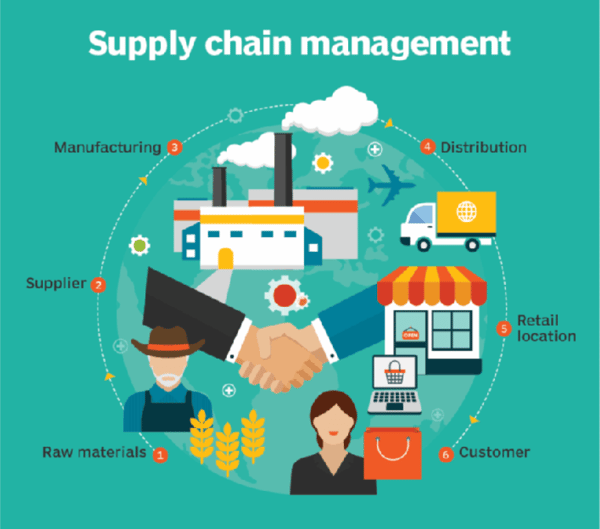

Supply chain management (SCM) is the broad range of activities required to plan, control and execute a product's flow from materials to production to distribution in the most economical way possible.

SCM encompasses the integrated planning and execution of processes required to optimize the flow of materials, information and capital in functions that broadly include demand planning, sourcing, production, inventory management and logistics -- or storage and transportation. Companies use both business strategy and specialized software in these endeavors to create a competitive advantage.

Supply chain management is an expansive and complex undertaking that relies on each partner -- from suppliers to manufacturers and beyond -- to run well. Because of this, effective supply chain management also requires change management, collaboration and risk management to create alignment and communication between all the participants.

In addition, supply chain sustainability -- which covers environmental, social and legal issues, in addition to sustainable procurement -- and the closely related concept of corporate social responsibility -- which evaluates a company's effect on the environment and social well-being -- are areas of major concern for today's companies.

Supply chain management produces benefits such as new efficiencies, higher profits, lower costs and increased collaboration. SCM enables companies to better manage demand, carry the right amount of inventory, deal with disruptions, keep costs to a minimum and meet customer demand in the most effective way possible. These SCM benefits are achieved through choosing effective strategies and appropriate software to manage the growing complexity of today's supply chains.

SCM has significant impacts on both the enterprise and the consumer.

Supply chain management activities can improve customer service. Done effectively, they have the ability to ensure customer satisfaction by making certain the necessary products are available at the correct location at the right time. By increasing customer satisfaction levels, enterprises are able to build and improve customer loyalty.

SCM also provides a major advantage for companies by decreasing operating costs. SCM activities can reduce the cost of purchasing, production and the total supply chain. Lowering costs improves a company's financial position by increasing profit and cash flow. Furthermore, following supply chain management best practices can minimize overuse of large fixed assets -- such as warehouses and vehicles -- by allowing supply chain experts to redesign their network, for example, to maintain customer service levels while operating five warehouses instead of eight, reducing the cost of owning three extra facilities.

Perhaps lesser known and underappreciated is SCM's critical role in society. SCM can help ensure human survival by improving healthcare, protecting people from climate extremes and sustaining life. People rely on supply chains to deliver necessities like food and water as well as medicines and healthcare. The supply chain is also vital to the delivery of electricity to homes and businesses, providing the energy needed for light, heat, air conditioning and refrigeration.

SCM can also improve quality of life by fostering job creation, providing a foundation for economic growth and improving standards of living. It provides a multitude of job opportunities, since supply chain professionals design and control all of the supply chains in a society as well as manage inventory control, warehousing, packaging and logistics. Furthermore, a common feature of most poor nations is their lack of developed supply chains. Societies with strong, developed supply chain infrastructures -- such as large railroad networks, interstate highway systems and an array of airports and seaports -- can efficiently exchange goods at lower costs, allowing consumers to buy more products, thus providing economic growth and increasing the standard of living.

Each major phase of a product's movement through the supply chain -- from materials to production and distribution -- has its own distinct business processes and disciplines. Most of them began decades ago as paper-based methods but now are usually handled in specialized software.

The SCM process starts with figuring out what products customers want -- the early stages of supply chain planning, traditionally considered one of the two overarching categories of SCM, along with supply chain execution.

Supply chain planning starts with demand planning, a process for gathering historical data, such as past sales, and applying analytics and statistical modeling to create a forecast or demand plan that the sales department and operational departments -- such as manufacturing and marketing -- can agree on. The forecast determines the types and quantities of products to be manufactured. Some companies perform demand planning as part of a formalized process called sales and operations planning (S&OP), which prescribes an iterative process of data gathering, discussion, reconciling of demand plans with production plans and management approval. Some companies include S&OP in a broader process called integrated business planning (IBP) that incorporates other departments' plans in a single, companywide plan.

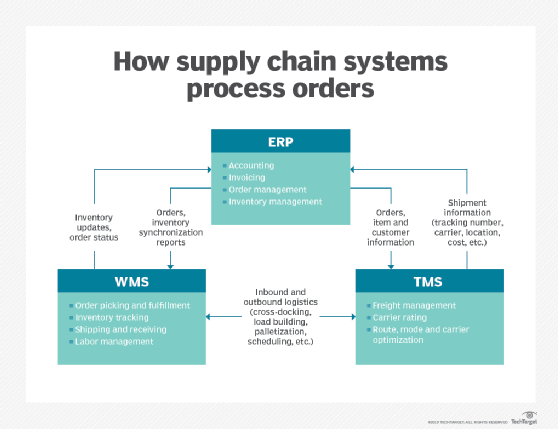

Technology is critical in managing today's supply chains, and every major supply chain management process has a software category dedicated to it. Most vendors of ERP suites offer supply chain management software, and there are thousands of niche vendors.

Besides managing specific processes, SCM software has an important role to play in tying together the people, processes, and systems that participate in the supply chain.

Other commonly used SCM modules include the following:

The increasingly global nature of today's supply chains and the rise of e-commerce, with its focus on nearly instant small deliveries straight to consumers, are posing challenges, particularly in the area of logistics and demand planning, while boosting demand for order management software capable of handling omnichannel commerce. A number of strategies -- such as lean manufacturing -- and newer approaches -- such as demand-driven material requirements planning -- may prove helpful.

There is a fair amount to account for in the planning process of supply chain. A multitude of facilities, if not all, are looking for ways to become better prepared for unforeseen obstacles and circumstances in their supply chains and similar challenges within their own respective location in the supply chain of their clients. Without some sort of a comprehensive plan, a facility might completely fail at order fulfillment; production suffers when the first unforeseen hurdle presents itself. This is exactly why obtaining an ERP system or system add-on that has suitable planning and production scheduling that can achieve the amount of comprehensive planning required is vital to profitability and timely order fulfillment. ERPs, typically, only go so far.

Facility wants and needs may not entirely match-up with any given in-house ERP system; therefore locating appropriate add-ons, such as advanced planning and scheduling systems (APS) can tend to fill gaps in those operational wants and needs that may be lacking. With an advanced planning and scheduling system, it can extend a given ERP system into a full-on supply chain planning and scheduling system for supply chain management (SCM). APS systems augment ERP systems with predictive analysis, simulations, and what-if scenario construction is one versatile feature of some APS systems offer, yet most ERP systems tend to lack with fine detail. APS systems tend to benefit production operations substantially through improved delivery performance, profitability, and reductions in inventory and labor cost.

Do you need an ERP add-on for planning and scheduling amid your supply chain? You are not alone.

View our schedule of industry leading free to attend virtual conferences.

Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

Watch On-Demand Recording - Access all sessions from progressive thought leaders free of charge

from our industry leading virtual conferences.

The premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free.

Use code: BFH1120

Delivered by the industry's most progressive thought leaders from the world's top brands.

Start learning today!

Welcome to BTOES Insights, the content portal for Business Transformation & Operational Excellence opinions, reports & news.

Insights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to attend this premier virtual conference, and they will receive an invitation to attend.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

View our schedule of industry leading free to attend virtual conferences. Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

View Schedule of EventsWatch On-Demand Recording - Access all sessions from progressive thought leaders free of charge from our industry leading virtual conferences.

Watch On-Demand Recordings For FreeDelivered by the industry's most progressive thought leaders from the world's top brands. Start learning today!

View All Courses NowThe premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free. Use code: BFH1120

Watch On-DemandInsights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to also access our newsletter. They will receive an invitation and an option to subscribe.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

Read this article about HP, Best Achievement in Operational Excellence to deliver Digital Transformation, selected by the independent judging panel, ...

Read this article about BMO Financial Group, one of our finalists, in the category Best Achievement in Operational Excellence to deliver Digital ...

Read this article about Cisco, one of our finalists, in the category Best Achievement of Operational Excellence in Internet, Education, Media & ...

50 Grosvenor Hill. London W1K 3QT.

United Kingdom.

Copyright 2023 Proqis®