Flow is one of the key tenets of lean. To that end, continuous improvement professionals exert enormous effort to improve both information and material flow in factories.

However, we don’t usually see as much effort in the office environment, where knowledge—not widgets—is the product, and the cost of poor flow is not as easily quantified. Information processes and flow are usually less-well defined in the first place, and often encrusted with bureaucratic barnacles that do nothing but impede flow.

Peter Drucker once quipped that, “Much of what we call management consists of making it difficult for people to work.” I suspect that Drucker was saying poor management makes it harder for people to work. Good management—a rarity—makes it easier. The truth is that all business processes require a certain amount of management structure to enable operations to flow smoothly, but often it’s the wrong amount of structure for the job at hand.

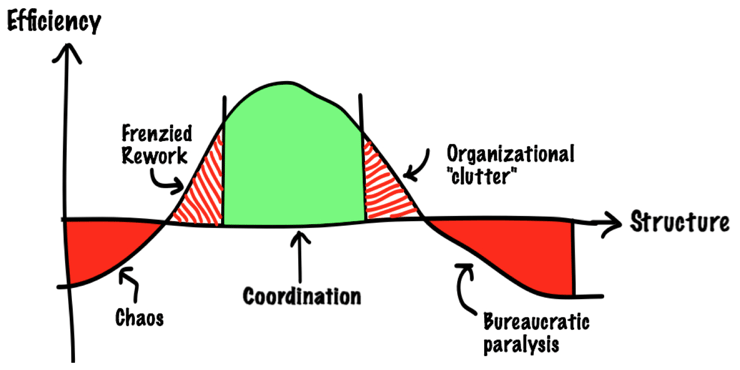

With no structure at all, you have total chaos—no one knows what needs to be done, who’s responsible for doing it, or even what the goals are. Many start up companies exist in this zone, although they’re often saved from disaster by virtue of having everyone sitting in the same room. They survive the lack of structure by virtue of easy, uncomplicated communication channels. As they grow, however, they either create appropriate process structures or they die.

When there’s just a bit of structure, the pain of rework bites hard. At a $500M footwear company I once worked with, the founder and CEO—long removed from his role product development—decided that he didn’t like a particular style his product team had designed, developed, and purchased. He diverted a container that was en route to the US with $400,000 worth of shoes to Africa, where he unloaded everything at a loss. The sales, marketing, product, and customer service teams were stuck at the 11th hour (well, the 12th hour, actually) adjusting for the CEO’s violation of structure.

Too much structure creates business “clutter,” which is typically manifested as excessive (and often low-value) meetings, the necessity of obtaining approvals from multiple tiers of management, an overload of initiatives, and a nearly suffocating volume of email. By now it’s practically a business fable, but when Alan Mulally took the reins at Ford in 2006, senior management actually had “meetings week”—five days each month in which executives held non-stop meetings. The preparation for that week, combined with the burden of having the leadership team unavailable for such a long period of time, hamstrung Ford’s ability to react to operational issues in a timely manner.

When structure reaches its extreme, the organization effectively suffers bureaucratic paralysis. Virtually nothing gets done. Government agencies are the poster children for this condition, although many companies experience it on a localized level. The stories are, in the most literal sense, nearly unbelievable: manager approval required for replacing an ID badge, or two approvals (!) needed to order new toner for a copy machine.

The right amount of structure for business processes fosters coordination without dangerous ambiguity or administrative burden. Looked at from a lean lens, this is the place on the continuum where the rules and structures create the most value with the minimum waste. WL Gore’s “lattice” structure of management is an excellent example of an organization in this position. The $3 billion company broadly distributes leadership responsibility throughout the organization, allowing employees to make “above the waterline” (i.e., low-risk) decisions on their own, and only requiring approvals for “below the waterline” (high-risk) decisions.

It would be nearly impossible for another company to copy Gore’s model of management. But it’s very much within the purview of the OpEx professional to apply this kind of thinking to the various office and administrative processes in any firm. It’s simply a matter of adding another layer of analysis to the standard value stream analysis that’s already being done.

View our schedule of industry leading free to attend virtual conferences. Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

View Schedule of Events-------------------------------------------------------

Search for anything

Insights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to attend this premier virtual conference, and they will receive an invitation to attend.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

View our schedule of industry leading free to attend virtual conferences. Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

View Schedule of EventsWatch On-Demand Recording - Access all sessions from progressive thought leaders free of charge from our industry leading virtual conferences.

Watch On-Demand Recordings For FreeDelivered by the industry's most progressive thought leaders from the world's top brands. Start learning today!

View All Courses NowThe premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free. Use code: BFH1120

Watch On-DemandInsights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to also access our newsletter. They will receive an invitation and an option to subscribe.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

Read this article about HP, Best Achievement in Operational Excellence to deliver Digital Transformation, selected by the independent judging panel, ...

Read this article about BMO Financial Group, one of our finalists, in the category Best Achievement in Operational Excellence to deliver Digital ...

Read this article about Cisco, one of our finalists, in the category Best Achievement of Operational Excellence in Internet, Education, Media & ...