BTOES From Home - SPEAKER ...

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

View our schedule of industry leading free to attend virtual conferences.

Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

Watch On-Demand Recording - Access all sessions from progressive thought leaders free of charge

from our industry leading virtual conferences.

The premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free.

Use code: BFH1120

Delivered by the industry's most progressive thought leaders from the world's top brands.

Start learning today!

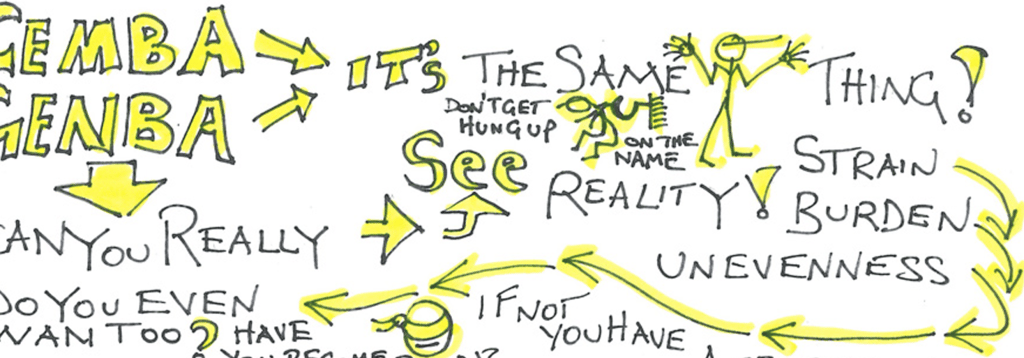

'Going to Gemba' is the act of visiting the shop floor in Lean and Kaizen. Literally translated as 'The Real Place', it pushes the importance of leadership understanding what is happening at every level.

Image credit: The Lean Post

Image credit: The Lean Post

Gemba (現場, also spelt less commonly as genba) is a japanese term meaning "the real place." Japanese police could refer to a crime scene as gemba, and TV reporters often refer to themselves as reporting live from gemba.

In business, however, gemba refers to the place where value is created. The most common use of the term is in manufacturing, where the gemba is the factory floor. Beyond this, gemba can really be any "site", such as a building site in construction, the sales floor in retail, or somewhere the service provider interacts directly with the customer e.g. a car dealership showroom.

READ MORE: Be A Rebel With A Cause: 7 Steps for A Successful Gemba Walk

READ MORE: What is Kaizen? Key Tools and Principles

VIDEO: Shut up and Go to Gemba, TEDx

In lean manufacturing, the whole point of gemba is that problems in a business process or production line are often easily visible, and the best improvement come from going to 'the real place', where leaders can see the state of the process for themselves.

"Go see, ask why, show respect"

Over the course of a Gemba Walk, leaders, managers and supervisors are expected to simply observe and understand process. As part of the Kaizen methodology, it is also supposed to encourage greater communication, transparency and trust between the lower-level of employees and leadership. For this reason, it is not appropriate to use a Gemba walk to point out employee flaws, or enforce policy - this runs the risk of employees putting up barriers to leadership, or closing off altogether.

Take a look at Mike Serena's best advice for a positive Gemba walk - read the full article here.

Welcome to BTOES Insights, the content portal for Business Transformation & Operational Excellence opinions, reports & news.

Insights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to attend this premier virtual conference, and they will receive an invitation to attend.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

View our schedule of industry leading free to attend virtual conferences. Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

View Schedule of EventsWatch On-Demand Recording - Access all sessions from progressive thought leaders free of charge from our industry leading virtual conferences.

Watch On-Demand Recordings For FreeDelivered by the industry's most progressive thought leaders from the world's top brands. Start learning today!

View All Courses NowThe premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free. Use code: BFH1120

Watch On-DemandInsights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to also access our newsletter. They will receive an invitation and an option to subscribe.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

Read this article about HP, Best Achievement in Operational Excellence to deliver Digital Transformation, selected by the independent judging panel, ...

Read this article about BMO Financial Group, one of our finalists, in the category Best Achievement in Operational Excellence to deliver Digital ...

Read this article about Cisco, one of our finalists, in the category Best Achievement of Operational Excellence in Internet, Education, Media & ...