BTOES From Home - SPEAKER ...

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

View our schedule of industry leading free to attend virtual conferences.

Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

Watch On-Demand Recording - Access all sessions from progressive thought leaders free of charge

from our industry leading virtual conferences.

The premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free.

Use code: BFH1120

Delivered by the industry's most progressive thought leaders from the world's top brands.

Start learning today!

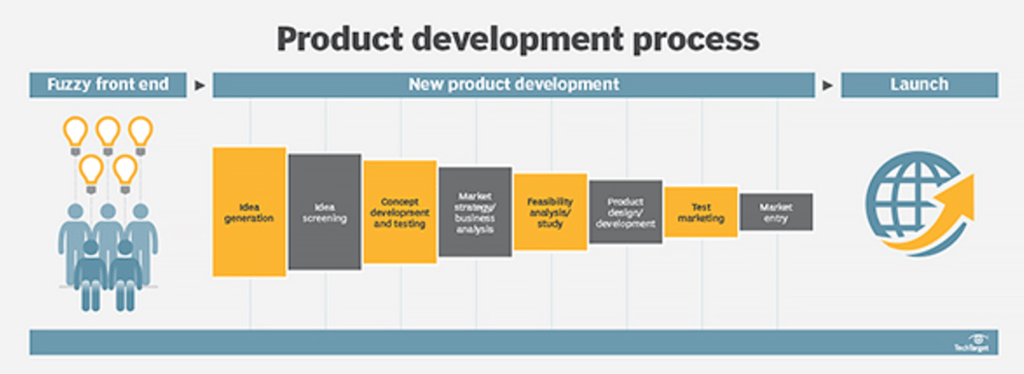

Lean Product Development focuses on using Lean to meet the need for innovative solutions, most often in a manufacturing process.

Image credit: TechTarget

Lean Product Development, or LPD, utilizes Lean principles to meet the ever-growing challenges of Product Development. Beginning with Allen Ward's study of the Toyota Production System, lean product development seeks to address the following issues in particular:

Although Lean Product Development does incorporate certain principles and guidelines of Lean Production, Lean Product Development focuses on the development of new products to suit the customer, as opposed to improving processes for existing products.

"Don't try to bring lean manufacturing upstream to product development. The application of Lean in product development and manufacturing are different. Some aspects may look similar, but they are not! Be leary of an expert with experience in lean manufacturing that claims to know product development"

- Jim Womack's advice to Harley Davidson

As Lean Product Development focuses more on innovation and the creation of new products, there are difference core principles, placed with differing priority to that of standard Lean Production. Below are these key principles, broken down into stages. To learn more about this list, click here.

First Principle: Define Value to the Customer

Third Principle: Make the Value Creating Steps Flow

Ultimately, the successful implementation of Lean Product Development should increase innovation within an organization tenfold, as well as facilitating the introduction of new products - potentially even at a 400-500% increase.

READ MORE: Great Scott! Potential Sighting of Lean Product Development!

Welcome to BTOES Insights, the content portal for Business Transformation & Operational Excellence opinions, reports & news.

Insights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to attend this premier virtual conference, and they will receive an invitation to attend.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

View our schedule of industry leading free to attend virtual conferences. Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

View Schedule of EventsWatch On-Demand Recording - Access all sessions from progressive thought leaders free of charge from our industry leading virtual conferences.

Watch On-Demand Recordings For FreeDelivered by the industry's most progressive thought leaders from the world's top brands. Start learning today!

View All Courses NowThe premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free. Use code: BFH1120

Watch On-DemandInsights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to also access our newsletter. They will receive an invitation and an option to subscribe.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

Read this article about HP, Best Achievement in Operational Excellence to deliver Digital Transformation, selected by the independent judging panel, ...

Read this article about BMO Financial Group, one of our finalists, in the category Best Achievement in Operational Excellence to deliver Digital ...

Read this article about Cisco, one of our finalists, in the category Best Achievement of Operational Excellence in Internet, Education, Media & ...