BTOES From Home - SPEAKER ...

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

View our schedule of industry leading free to attend virtual conferences.

Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

Watch On-Demand Recording - Access all sessions from progressive thought leaders free of charge

from our industry leading virtual conferences.

The premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free.

Use code: BFH1120

Delivered by the industry's most progressive thought leaders from the world's top brands.

Start learning today!

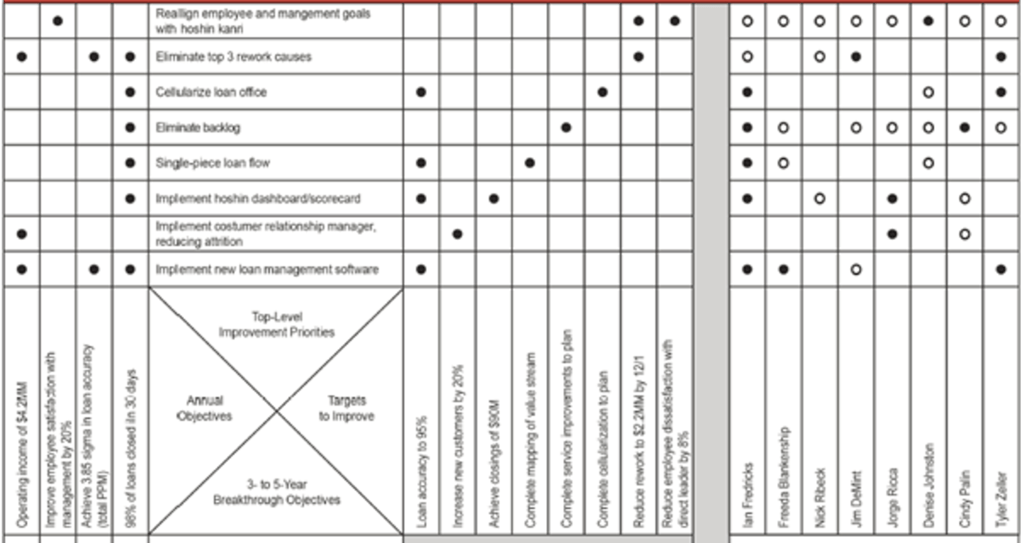

Hoshin Kanri, also known as Policy Deployment, is another aspect of Lean that is designed to ensure the strategic goals of a business are driving progress and action - at every level.

Image credit; BMGI

Image credit; BMGIHoshin Kanri (Japanese: 方針管理) is a 7 step process used as part of Strategic Planning, in which goals are communicated and shared throughout the company, and then put into action. The purpose of Hoshin Planning is to improve communications throughout the company, whilst also reducing the waste created by poor direction or bad management at any level. For this reason, companies that use Hoshin Kanri often follow a Think, Plan, Implement, and Review process.

Read More: What is Gemba - Definitions and tools

Video: How to Apply Hoshin Kanri, Gemba Academy

With Hoshin Planning, the goal is to share goals down from the top level, whilst simultaneously sharing results from the shop floor up to the management. Much like the veins and arteries in the human body, this flow should permeate and unite all levels of the organization, by aligning the goals of the company (Strategy) with the plans of middle management (Tactics) and the work performed by all employees (Operations).

In this way, Hoshin is unique amongst Lean tools, as it discusses more explicitly the opening of communications and discussion of goals, rather than the actual process implementation itself.

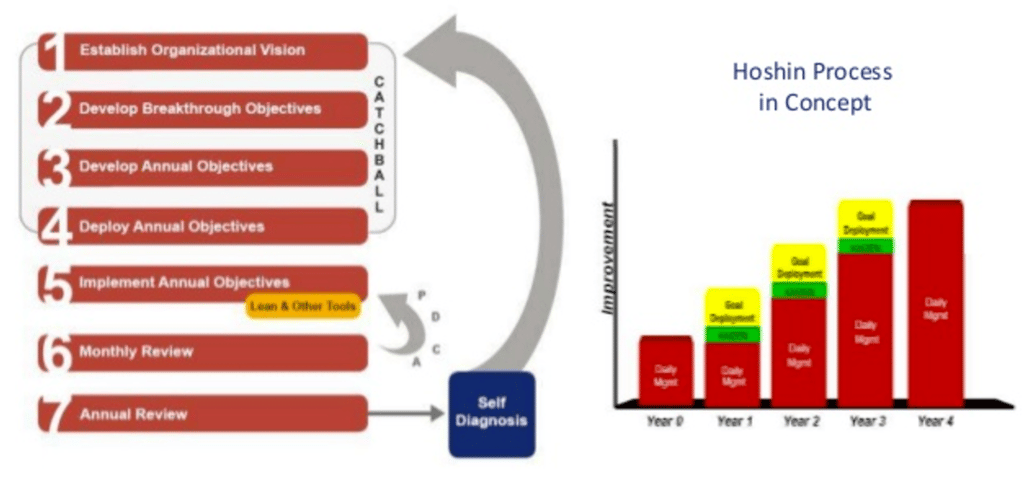

A Standard Hoshin Process: Credit I-Nexus

A Standard Hoshin Process: Credit I-Nexus

4 Steps to Hoshin Planning

Below are some typical implementation steps that take place when establishing Hoshin Kanri within an organization, Strategic Planning, Tactical Development, Taking action, and Reviewing to Adjust.Hoshin Kanri is begun with a Strategic plan, often set annually, by the Top level management. The goals should be within limits (5 goals or less as best practice), focused on effectiveness, and agreed between all levels of management, to ensure they are realistic and achievable.

Once these targets have been set by the top tier, it is up to middle managers to develop the tactics that will best achieve these goals. Communication is key, to ensure that goals and strategies are realistic, as well as well understood by all levels of the business.

At the plant/shop floor level, supervisors and team leaders should then work out the operational details, to ensure they are both aligned with the established goals and tactics, as well as realistic and achievable. This is the stage known as going to 'Gemba', where the goals are actioned at the real place.

At this point, the results and statuses on the projects are then fed back up the tiers of the company. This ensures the 'Closed Loop' system is in place, allowing top management to review the progress of the shop floor operations, and adjust their goals and tactics accordingly.

Welcome to BTOES Insights, the content portal for Business Transformation & Operational Excellence opinions, reports & news.

Insights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to attend this premier virtual conference, and they will receive an invitation to attend.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

View our schedule of industry leading free to attend virtual conferences. Each a premier gathering of industry thought leaders and experts sharing key solutions to current challenges.

View Schedule of EventsWatch On-Demand Recording - Access all sessions from progressive thought leaders free of charge from our industry leading virtual conferences.

Watch On-Demand Recordings For FreeDelivered by the industry's most progressive thought leaders from the world's top brands. Start learning today!

View All Courses NowThe premier Business Transformation & Operational Excellence Conference. Watch sessions on-demand for free. Use code: BFH1120

Watch On-DemandInsights from the most progressive thought leaders delivered to your inbox.

Insights from the world's foremost thought leaders delivered to your inbox.

Being a hero is all about creating value for others. Please invite up to 5 people in your network to also access our newsletter. They will receive an invitation and an option to subscribe.

If it’s easier for you, please enter your email address below, and click the button, and we will send you the invitation email that you can forward to relevant people in your network.

Courtesy of Nintex Pty's Paul Hsu, below is a transcript of his speaking session on 'Improve employee productivity during and post-COVID by ...

Read this article about HP, Best Achievement in Operational Excellence to deliver Digital Transformation, selected by the independent judging panel, ...

Read this article about BMO Financial Group, one of our finalists, in the category Best Achievement in Operational Excellence to deliver Digital ...

Read this article about Cisco, one of our finalists, in the category Best Achievement of Operational Excellence in Internet, Education, Media & ...